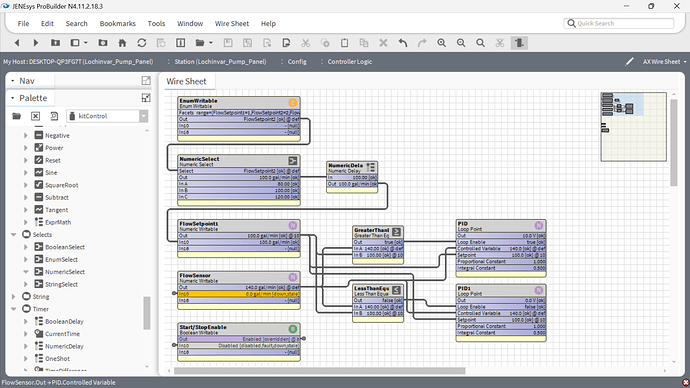

Hey guys, I’m very new to controls and I am trying to write a simple pump control program. I am getting hung up on the PID. I can’t seem to get it to ramp down. Right now I’ve got two PIDs, one enables when the flow is above setpoint and the other enables when it is below. It is going to be sending a 0-10vdc signal. Can someone please point me in the right direction? I haven’t been to N4 school yet, but I’ve watched a lot of OneSight’s YouTube videos and I’ve done several of the challenges on this forum. Thanks in advance!

I usually haven’t seen pumps maintain a flow rather a differential pressure. However, I would assume you need a reverse acting loop. As far as proportional constant you’ll want to adjust this on how quickly or slowly you like your output to change based on deviation. For example for every 1 GPM you are off, with a constant of one and integral of 0, it will output 1 percent.

So here I would think if your maintaining flow, you may want a larger proportional.

The integral is in repeats per minute. Which means at .5, you’d only go up or down 1 percent every two minutes. Quite slow there.

Did you try it without the Greater than/ Less than ? Feed it straight into a single PID ? That’s what the PID does. Ramp up/ ramp down.

The two sep PIDs could be bucking each other near setpoint, as well as the math. Flipping back and forth between GT/LT with no delay timer. That will confuse the response time.

You should be able to feed that into 1, and tune it from there. I think your PI terms are right for a starting point, and generally speaking for HVAC if you need a D…something’s off in your P or I.

Sometimes, our minds make it more complicated than it is.

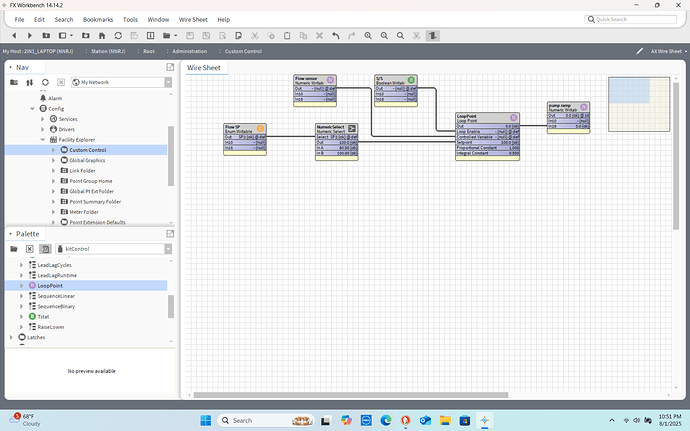

Hey yes! Thank you. I made it a reverse acting and it started working just fine. I also took the greater/lesser than blocks out and made it a single PID. Thanks for your help!